Design and Planning

GAS TRANSMISSION SERVICES, PIPELINE DESIGN AND CONSTRUCTION

Rush Construction Services have designed and project managed new-build large diameter gas pipeline projects and high Pressure Reduction Installations, along with numerous pipeline diversions and PRI modifications. Our expertise in this field is known and recognised throughout the UK Gas Industry

450NB FEEDER 18 PIPELINE DIVERSION DETAILED DESIGN:

Our client was required to divert a 450NB HP feeder pipeline, in order to facilitate a road upgrade.

The existing 450NB pipeline was constructed from linepipe of standard wall thickness and therefore needed to be replaced with heavy wall pipe at locations affected by the proposed road scheme to comply with the requirements of IGEM TD/1 Edition 5.

Rush Construction Services Ltd (RCS Ltd) were commissioned to carry out a detail design study (DDS) for the diversion beneath the proposed dual carriageway. Two designs were developed in conjunction to assist our client in identifying the most cost-effective option. The options considered either installing the pipe by means of open-cut or by Horizontal Directional Drill (HDD).

The pipeline was tied-in by means of an end on connection, due to the pipeline being subjected to pigging operations, and the tie-ins were made during a pipeline outage.

The effectiveness of installing the pipe by means of an HDD was reviewed in conjunction with an interim ground investigation report and the conditions were found to be favourable.

PIPEWORK STRESS & FINITE ELEMENT ANALYSIS (FEA)

Rush Construction Services provide CAESAR II pipework stress analysis services in accordance with IGEM standard TD/12 and GDN specification PW/13 to assess stresses in 3D pipework models to ensure code compliance prior to construction.

Rush Construction Services are well versed in the use of FEA software and manual stress calculations to resolve code stress exceptions arising from pipework stress analysis. FEA software is employed at Rush to assess non-pipework components such as bespoke pipe support designs.

Design of a gas supply to a new 300MW open cycle gas turbine

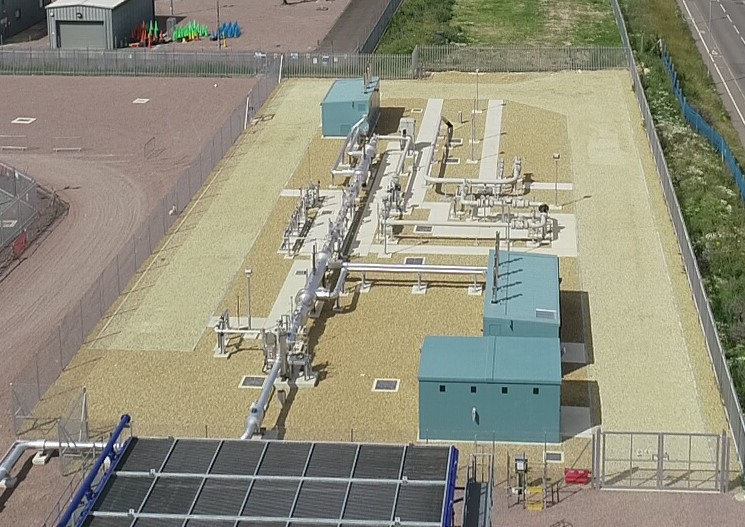

RCS completed the Design of a gas supply to a new 300MW open cycle gas turbine as part of a Gas Turbine Expansion Project at Spalding. The design included the connection to an existing above ground installation, a new 70bar pipeline, and a new Gas Receiving Facility (GRF) for the new turbine.

The new GRF included filtering, a fiscal metering system, pressure reduction, a bespoke two-stage heating system and all associated electrical, instrumentation and telemetry systems.

The new GRF and pipeline were designed to the requirements of IGEM/TD/1, IGEM/TD/13, IGEM/TD/12 and IGEM/SR/25.

FEASIBILITY STUDY INTO THE CONSOLIDATION OF PRESSURE REGULATING EQUIPMENT AT FULHAM GAS HOLDER STATION

Rush Construction Services were commissioned by National Grid to undertake a feasibility study into the consolidation of pressure regulating equipment at Fulham gas holder station (formerly Fulham gas works) following a decision by the client to demolish, remediate and develop the former gas holder site into high-rise residential apartments in conjunction with Berkeley Group. Subsequently, Rush were commissioned with the follow-up conceptual and detail design studies in relation to the construction of a brand new HP/IP/MP/LP PRS incorporating a 30” HP inlet pig trap facility, 24” filter streams, 24” buried HP/IP control valve streams, non-fiscal metering, multiple buried IP/MP & IP/LP regulator streams and local gas treatment facility. As well as the mechanical pipework design, the project included all associated civil, electrical, instrumentation (telemetry) and cathodic protection engineering design disciplines.

Due to the location of the new PRS and the fact that the high-rise residential apartments would overlook the site, noise and aesthetics played an important role in development of the design. Rush worked closely with equipment suppliers and noise consultants to develop 3D models of predicted noise levels at nearby receptors, as well as accommodating architects’ specifications for the overall site finish and boundary wall.

We were also part of the team involved in the diversion of the incoming 30” Richmond to Fulham high pressure pipeline and routeing of the outgoing medium and low pressure mains to minimise their impact on the proposed development layout.

Designs were produced in accordance with IGEM standards TD/13, TD/1 & TD/3 and all relevant client specifications, including design approval/appraisal in accordance with IGEM/GL/5.

Rush Construction Services are well versed in the use of FEA software and manual stress calculations to resolve code stress exceptions arising from pipework stress analysis. FEA software is employed to assess non-pipework components such as bespoke pipe support designs.

Distribution Network Design: New Gas Infrastructure Operating Up To 7barg

We have designed gas network schemes for many domestic housing, commercial and industrial projects and are now the sole gas utility designer working on the largest private finance initiative scheme ever let in Europe.

Rush Construction Services are fully accredited for Design under the Gas Industry Registration Scheme (GIRS) which is administered by Lloyds Register. In addition to the high pressure work detailed earlier, we also design new gas infrastructure operating up to 7barg for installation by Utility Infrastructure Providers, which is then adopted by Gas Transporters without the need for the extensive detail normally required.

If you are a Developer of Residential Housing, Industrial Complexes, Commercial Retail Parks, etc., then please refer to our “Services for Developers” page.